Description

Our BDSA OMEGA-D is a compact, automatic, electrically-controlled brewery with three structural tanks. This is the most complete model in the electric range, incorporating all possible extras.

The available version includes 3 thermally insulated tanks.

The upper doors are made of glass.

The two transfer pumps are made by EBARA.

BDSA OMEGA-D incorporates a platform that provides access to the top hatches of the MASH and BOIL tanks, a series of stainless steel pipes connected to the two transfer pumps, which enable transfer operations during the production process, a plate heat exchanger (whose size varies according to volume) that enables wort cooling after the boiling phase, and Whirlpool.

The MASH (brewing and filtration) tank is equipped with a gearmotor and agitator to homogenize the brew.

The integrated filter, with its modern design and easy handling, filters the wort. The spent grains are discharged through the rectangular door.

All operations are carried out via the touch screen and management software. The software allows you to program all process phases, save numerous recipes and record the process for future analysis.

In addition, this model includes the network connection module (for remote supervision, diagnostics and error correction), the spent grain evacuation system and commissioning.

This automatic brewery is available in useful models of 300L, 500L and 1000L, and can also be designed for 1500L production (depending on the electrical power available in your hall and the technical characteristics of your installation).

Like the rest of our production, the BDSA-Omega Brewery is manufactured according to the highest industrial and environmental standards.

Made of 304L stainless steel with 2B finish

High-quality, European-produced stainless steel.

BDSA OMEGA D automatic brewery with Touch screen and management software.

-Manufactured in stainless steel AISI 304L EN 1.4307 OUTOKUMPU (Finland)

Three-phase electrical operation.

-Steel pipes and valves linking tanks with TRI-CLAMPS connections.

-2 Pumps for hot liquids, with electronic variable speed drive, controllable via PLC display.

-Stainless steel support structure with access step.

– Automatic control panel with OMEGA touch screen

-Flowmeter ≥80 degrees

-Automation of mashing/boiling/hot water functions.

-Programming of the various production phases. -Introduction and recording of 50 recipes.

Precise control of electrical resistors with variable resistor power, with the option of manual intervention during the recipe, to modify parameters if necessary by pausing the automation.

-Delayed start program (up to 72 hours).

Dimensions : -Varies according to model

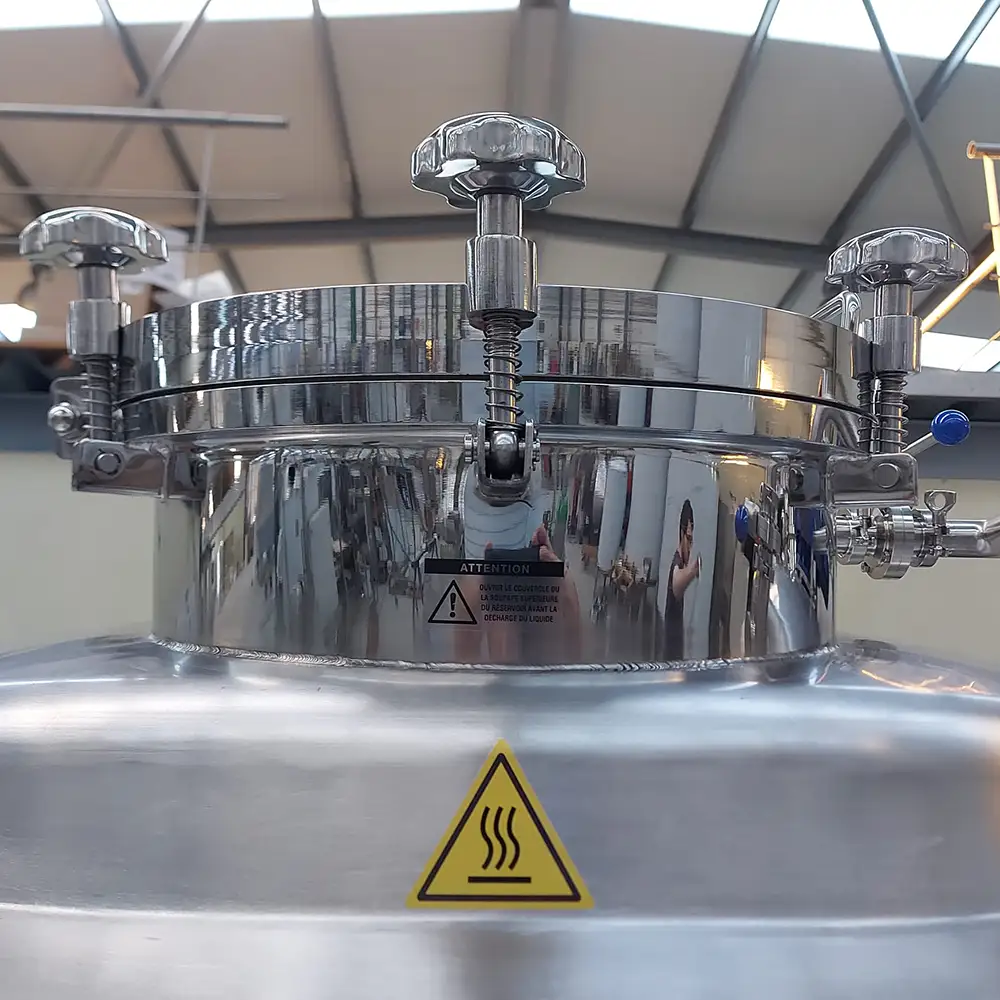

Isothermal boiling tank with 50mm polyurethane insulation

-Whirlpool system

Three-phase resistors variable according to model

– Ø1″ rotating wash ball

– 400mm glass top hatch

– Butterfly valves DN40 TRI-CLAMP 1″1/2 –

Chimney flue with Clamp outlet for connection to steam extraction system.

-Isothermal brewing tank with 50mm polyurethane insulation.

Three-phase resistors, variable according to model

– 300mm glass top hatch

– 230V gear motor with agitator, Ratio 1/80

– Sparging system (washing ball)

– Ø1″ rotating wash ball

-Butterfly valves DN40 TRI-CLAMP 1″1/2

– Rectangular door

– Removable spent grain filter

-Skidding aid system with variable speed 1/2 rotation

Approximate dimensions :

Isothermal electric hot water tank with 50mm polyurethane insulation.

Three-phase resistors, adjustable according to model

-Ø1″ rotating wash ball

– 400mm glass top hatch

-Butterfly valves DN40 TRI-CLAMP 1″1/2

Included:

-Buffer tank on wheels with removable filter

Structure-integrated plate heat exchanger with 37 3-PASS plates

-Stainless steel sight glass, motorized valve, temperature sensors (control the temperature of the wort leaving the plate heat exchanger),

-Internet remote control interface (for technical support / remote updates)

Start-up with brew. Includes: transfer of 1 brewery technician after delivery, including transport, accommodation and maintenance.

TIG WELDING PROCESS

STANDARD FINISH:

Exterior finish in natural 2B stainless steel / Ra polish <0.8μm;

Interior finish – Ra <0.5 μm;

-2R bright annealed finishes available on request

Related products:

-FERIM (Isobarometric fermenter)

-FERATM (Atmospheric fermenters)

-CBS (Cuve de Brassage à Gaz)

-CES (Gas Boiling Tank)

CFS (Gas-fired hot water tank)

-CESP (Electric Boiling Tank)

-CFSP (Electric Hot Water Tank)

-CBSP (Electric Brewing Tank)

-Capper

-Embuteilleurse

-Labeller

-AG-DRD (Sistema di ayuda de evacuación de cereal)

-Commissioning

-Accessories